Ever wonder what goes into shielding for a PET imaging facility?

No? Well, I’m going to show you anyway.

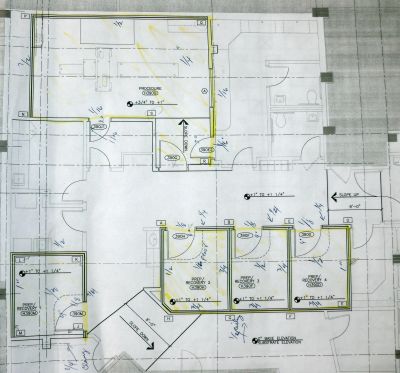

First you need to find a Qualified Medical Physicist (like me) to develop a shielding design for you. The shielding design gets turned into a set of blueprints for the lead contractor to work with.

Then you need lead. Lots and lots of it.

This is a layer of 1/4″ thick lead sheet lining the floor. The strips cover up the seams between the lead sheets so that there are no gaps. Depending on what’s underneath, the floor may require as much as 1″ of lead.

For the walls, you’ll need stacks of 1/4″ or 1/2″ lead sheet attached to 3/4″ plywood, like these

Thinner lead sheets are usually glued to drywall, but that doesn’t quite cut it for the thicknesses required for PET shielding.

The lead/plywood sheets go up like this

The sheets are also interlocking to eliminate the gap between sheets

Depending on what’s on the other side of the wall, you’ll need bricks too. This is a stack of 1″ interlocking bricks. Sometimes your wall might even need up to 2″ thick bricks.

This is what the brick wall ends up looking like

The bricks are screwed into the metal studs for support. Thicker brick walls require additional support and are usually constructed between two sets of studs.